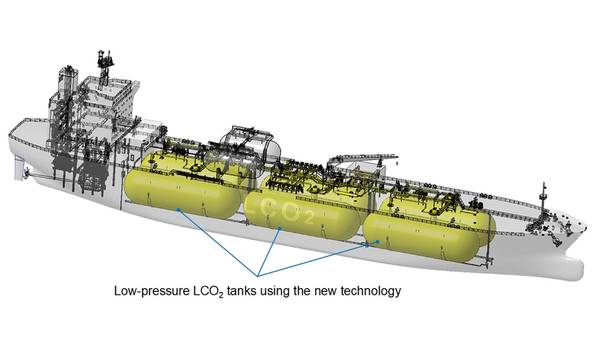

Mitsubishi Shipbuilding Co., Ltd., part of Mitsubishi Heavy Industries (MHI) Group, and Nippon Steel Corporation have received the world’s first General Design Approval (GDA) from ClassNK for a breakthrough tank technology that enables the manufacture of large low-pressure liquefied CO₂ (LCO₂) cargo tanks without post-weld heat treatment (PWHT). The achievement marks a significant step toward scaling up CO₂ transport capacity to support global carbon capture, utilization and storage (CCUS) value chains.

At the core of the innovation is a newly developed high-strength steel—conforming to Nippon Kaiji Kyokai (NK) standard KF460—engineered by Nippon Steel to deliver high strength, exceptional low-temperature toughness and cost efficiency. Mitsubishi Shipbuilding applied this steel to large LCO₂ tank structures and performed an Engineering Critical Assessment (ECA) to validate structural integrity without PWHT, a process traditionally mandated by the IGC Code for carbon-manganese steel welds.

PWHT has long been a bottleneck in the scale-up of LCO₂ carrier designs. Few heat-treatment furnaces worldwide are capable of annealing tanks of the size required for next-generation CO₂ carriers, constraining shipyard productivity and limiting vessel capacity. By eliminating the need for PWHT through ECA-based justification, Mitsubishi Shipbuilding and Nippon Steel aim to streamline production, reduce manufacturing costs and support the rapid growth of the CO₂ shipping segment.

The GDA from ClassNK confirms that the PWHT-exempt tank design meets safety, strength and reliability requirements, making it the first approved solution of its kind globally. Mitsubishi Shipbuilding said the technology aligns with its broader cross-industry program to standardize large LCO₂ carriers, reduce transport costs and accelerate market adoption of CO₂ shipping as a key component of CCUS infrastructure.

Both companies plan to work with supply-chain partners to commercialize the steel and tank design, supporting shipyards and equipment manufacturers as LCO₂ carrier demand expands.

The project also reflects the MHI Group’s wider strategy to advance energy-transition technologies—from carbon transport to next-generation marine engineering—through technical collaboration and global partnerships. Mitsubishi Shipbuilding said the milestone underscores its commitment to delivering practical, scalable technologies that enable the maritime sector’s decarbonization pathways.