International oil services group Aker Solutions is about to open North America's most advanced drilling equipment simulator in Houston, Texas. The simulator will be available to rig operators with the objective of making offshore drilling operations safer and more cost effective.

Aker Solutions is investing USD 2.5 million in the new state-of-the-art drilling equipment simulator, which will be available 24/7 for North American based rig operators and oil companies. It will double the capacity of the current training centre located in Katy near Houston. The new drilling simulator is expected to be officially opened early 2012.

"This will be the most advanced drilling simulator in North America and we will double our training capacity when it is ready for use. It will have dedicated staff who can provide round-the-clock service on Aker Solutions' complete range of topside drilling equipment. We look forward to start working with our customers in this new and upgraded centre," says Glenn Ellis, head of drilling technologies for Aker Solutions in the US.

Aker Solutions is one of the world's top providers of drilling equipment packages and technologies for deepwater drilling operations. Using advanced 3D visualisation technology, the company has developed the market leading drilling simulators, which are already in operation in Brazil, Singapore, Norway and South Korea, in addition to Houston. A new simulator is also being prepared in Baku, Azerbaijan.

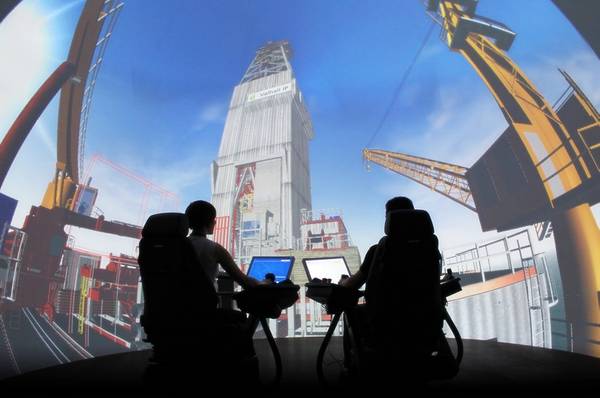

The centrepiece of the 9,800 square foot training centre is a new 240 degree domed simulator. Its dome-shaped screen, combined with utilization of actual drilling control systems software, creates a realistic environment that emulates what is experienced on a rig. Each specific rig is meticulously recreated as a virtual asset, including all rig equipment and control systems. This offers the possibility of onshore training and detailed operational planning, with the same signal treatment, in virtual environments that are identical to those that will be experienced offshore.

The training centre's extensive server systems are made up of 88 individual servers, which provide enough capacity to run simulations on two drilling rigs simulator systems simultaneously. A manual switchover solution allows quick change of the rig configuration in the simulator to ensure maximum simulator utilisation.

"A realistic, real-time visualisation of drilling operations enables rig operators to learn to make better and faster decisions. The result is safer operations, more efficient drilling and increased rig uptime. This simulator technology certainly allows us to offer superior training facilities for our clients and our own employees," adds Glenn Ellis.