As the maritime sector implements strategies to move away from its dependency on fossil fuels, North Star, the UK’s largest offshore installation infrastructure services company, is a frontrunner with its decarbonization program well underway.

While its new offshore wind fleet, which is being delivered from early 2023, has been specifically designed with sustainability and future fuels in mind, the vessel operator is also fully committed to the green transformation of its existing Emergency Response and Rescue Vessel (ERRV) tonnage.

The carbon neutral status of its onshore operations in Aberdeen, Newcastle and Lowestoft has also been internally scrutinized and the business is in the process of hiring a sustainability lead to keep driving its culture of climate resilience forward.

North Star, which employs circa 1,300 crew and personnel has a proud heritage. It was established over 135 years ago to provide support to the North Sea fisheries industry. When the region’s oil and gas sector emerged in the 1970s, the firm seized the opportunity to adapt its tonnage and widen its maritime skills to support the boom in oil and gas exploration and production work. Today, it boasts the largest UK-wholly owned marine fleet, delivering around the clock operations and exceptional ship management, and in-house repair facilities.

It's ERRV fleet is the largest in the UKCS and provides essential crew rescue, firefighting, and other emergency response services to over 50 North Sea installations 24/7, 365 days a year.

The business has completed an in-depth independent study with Houlder Ltd. to help determine the carbon emission reduction opportunities across its current 41 vessel fleet. The findings have highlighted the most effective green innovations for the firm to invest in over the next decade. Implementing the greenhouse gas reduction recommendations will help the business further its own journey to net zero by 2040 while maintaining its competitive edge and delivering on the wider maritime sector’s decarbonization objectives.

North Star ERRVs and supply vessels support 50 UK offshore installations (Copyright North Star, courtesy of North Star)

North Star ERRVs and supply vessels support 50 UK offshore installations (Copyright North Star, courtesy of North Star)

Hybrid-Powered Ships

With the challenge of the country’s energy security well documented in recent months, the conversations around the energy transition have changed tack. Although the oil and gas sector remain core to North Star’s business, it has now secured market share within the offshore wind sector which will be a major growth avenue for the organisation going forward.

In the offshore renewable/SOV sector, North Star was awarded four long-term contracts for its new hybrid-powered ship design. Breaking the company into the renewables market for the first time, its solution provides comfortable, floating-hotel style accommodation to offshore wind technicians maintaining wind turbines and sub stations in field, and a centralized logistics hub to travel to and from work each day across a “walk-to-work” gangway, or transfer via a smaller daughter craft vessel. The SOVs are also configured to act as a warehouse and handle cargo from a side access similar to that found on an aeroplane for transferring luggage into the hold.

As SOVs operate consistently within the same wind farm throughout their 10-year charter period, they could operate well on batteries once in-field charging stations are available. North Star’s design has embedded energy storage space which will make conversion from sole diesel reliance to becoming a multi-fuel system in the future using an alternative feedstock such as methanol or hydrogen.

The newbuild design is curated for shore-based power connectivity; the next step is an offshore connection and North Star has joined an industry steering committee to progress in-field battery charging.

Coupled with in-field fuelling as well as increased onshore and offshore automation, the development of zero carbon power and propulsion technologies will achieve a faster decarbonisation journey.

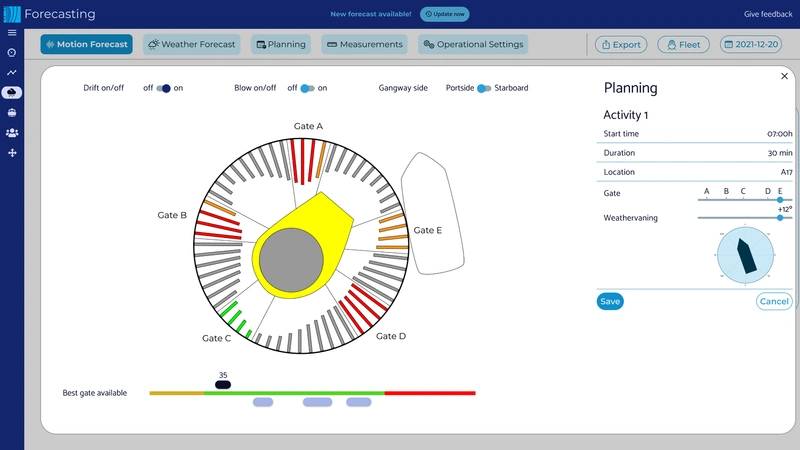

MO4’s decision support software will help to optimise efficiencies across North Star’s offshore wind fleet (Copyright MO4, courtesy of North Star)

MO4’s decision support software will help to optimise efficiencies across North Star’s offshore wind fleet (Copyright MO4, courtesy of North Star)

SOVs and the Digital Revolution

North Star is committed to identifying areas where sustainability can be improved, with a drive to find new, innovative, ecological solutions which enhance sustainability across its business and stakeholders.

During the concurrent 10-year campaigns for its initial four SOVs, the vessels will typically operate with between 50 and 75 crew and passengers on board for a 14-day duty cycle. Loaded up with cargo and supplies, the vessels will bunker fuel in port before transiting to the wind farm in UK waters.

Once in situ, the SOVs will travel between wind turbines while in dynamic positioning (DP) mode and overnight, they will be stationed at a safe distance from field infrastructure on standby consuming less energy.

To support the efficient running of these vessels, the company has invested in a unique digital twin and decision support software package, which will be installed on all four assets.

Developed by MO4 and believed to be the first of its kind used for the SOV market, the digital software package will provide predictive maintenance support to help drive efficiencies across the fleet including lower carbon emissions through reduced fuel usage.

Aligned to North Star’s objective to aim ‘above and beyond’ with respect to SOV industry standards, MO4’s user friendly and highly accurate solution will ensure operations are performed continuously within safety limits but without excess conservatism, thereby making a step-change in operational efficiency.

The digital solution gathers data from all four SOVs on influential areas such as weather fronts, workloads, work routes and drop-off schedules. The information is collated and linked to the spatial model to predict future behaviour. By monitoring the simulated data, and harmonising across the fleet, the ongoing AI learning will also help to increase in-field efficiencies further.

Emission Reduction Technology

North Star’s ERRV fleet provides 24/7, 365 service, and typically operate on a 28-day duty cycle in which they crew change, bunkers and loads essential supplies in port before travelling to the offshore installation where they remain on standby until a relief vessel takes over and they return to port to repeat the cycle. These ships also typically operate on the same cycle where they transit between offshore installations to provide standby cover for approximately 24-72 hours at a time before transiting on, spending a higher proportion of their time – and fuel - on route compared to the normal ERRVs.

Real time measurement of fuel burn is central to understanding the implications of decisions on operational performance. A full range of innovative emissions reduction technologies and approaches are being considered and assessed for their suitability on each vessel class in North Star’s fleet. These range from low-cost interventions to large equipment retrofit projects. The decision on which route to take will be dependent on the asset and technologies adoption.

The company is also considering investing in a version of its AI software to help modernise and optimize its ERRV tonnage to further improve performance and reduce the cost of maintenance programmes. North Star’s decarbonisation strategy is critical to the success of the business (Copyright North Star, courtesy of North Star)

North Star’s decarbonisation strategy is critical to the success of the business (Copyright North Star, courtesy of North Star)