In the data infographic, released by Shipbuilder, you can discover the most notable advantages of switching to data-driven operations for maritime companies.

Geert Schouten, director of Shipbuilder: ”We have been active in the maritime sector for eight years now and help shipyards and yacht builders to digitally transform, from document-driven to data-driven. For them this means making business future proof with the help of our knowledge based data management system. They turn away from keeping track of all data in email, Word or Excel or even odder, within binders. We have transformed our experience with the advantages of smart digital transformation into an infographic.” We gladly list the top three reasons why maritime companies should now make the switch to data-driven work below.

Work with a smile

It may look strange that we start with this, yet it makes perfect sense. Schouten: “Imagine you have to search for data hidden in binders for an average of three hours every day. And imagine that when you finally find the data, you have to ask yourself every time whether it’s the latest version of that information. Does that make you happy? Unfortunately, for many maritime engineers this is the tough, daily reality. The switch to the Shipbuilder smart data management program, provides them with a time saving factor of six. Now the search for the correct, up-to-date(!) information only takes half an hour a day. This means that throughout the day you will immediately find what you need. Throw your frustrations overboard and work with a smile.”

Trust your data

Of course, you want to find the data you are looking for immediately. However, an Excel or Word file, does not automatically keep track of whether there are multiple versions of a file in circulation in a company or what part of the file has changed. A problem that does not affect a data management system (such as Shipbuilder) at all. Only one truth is possible in the system. Simply put: you always have the latest information that you can work with real-time. And most importantly, you can always trust the data.

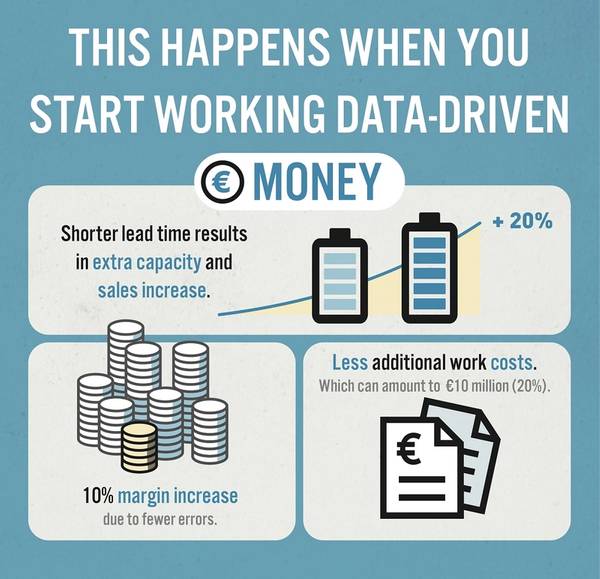

Money!

How does 5.000.000, - sound to you. Maybe a downer, but this is what is lost on an average maritime project of fifty million Euro due to the use of incorrect and unreliable data. The positive side is that if you switch to data-driven operations, you can easily prevent these costs. In fact, data-driven work ensures projects can be delivered five months earlier and achieving a capacity increase of twenty percent. Money, money, money!