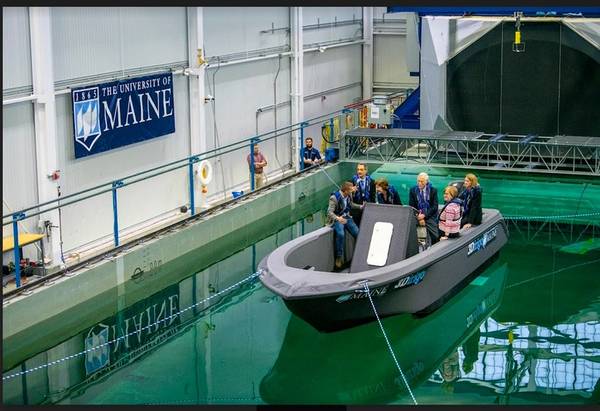

Vessels fashioned in a 3D printer, rather than a shipyard, will be the subject of a presentation at a Worldwide Ferry Safety Association (WFSA) event. The virtual gathering, Innovations in Ferry Design and Vessel Construction, will be held in conjunction with the presentation of awards inWFSA’s Annual Student Design Competition, now in its ninth year, to be held on May 18, 2022.The keynote speaker…

Norway-based global maritime industry group Wilh. Wilhelmsen Holding ASA announced that Berge Mafadi, a Berge Bulk vessel has received the world’s first commercial delivery of 3d printed scupper plugs, as part of Wilhelmsen’s Early Adopter Program…

The international accredited registrar and classification society DNV GL has awarded thyssenkrupp, German multinational conglomerate, first additive manufacturing approval of manufacturer certificateThe shipping industry is looking to take advantage of additive manufacturing (AM)…